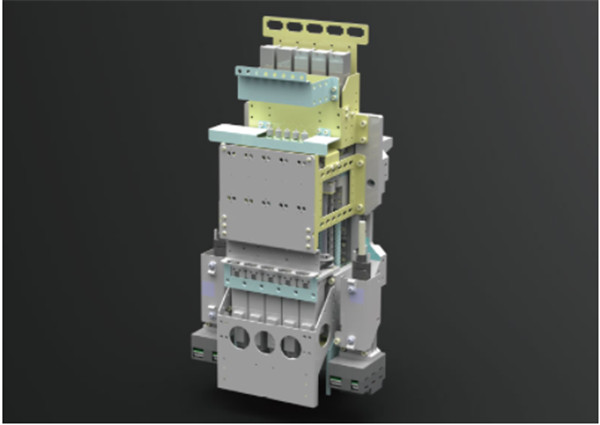

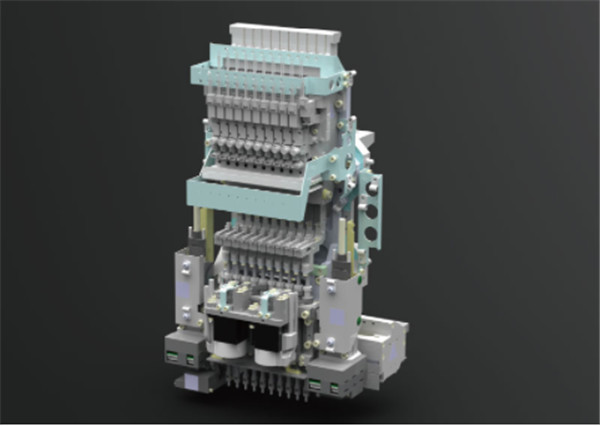

Two types of heads are available that bring the "1-head solution" to an even higher dimension capable of accommodating a wide range of components while maintaining high speed with no head replacement. High-speed general-purpose heads can be used for ultra-small (0201mm) chip components. This universal type head made for high-speed mounting and versatility supports from ultra-tiny chips of 0201mm to large-size components of 55 x 100 mm and height of 15 mm.

Two types of heads are available that bring the "1-head solution" to an even higher dimension capable of accommodating a wide range of components while maintaining high speed with no head replacement. High-speed general-purpose heads can be used for ultra-small (0201mm) chip components. This universal type head made for high-speed mounting and versatility supports from ultra-tiny chips of 0201mm to large-size components of 55 x 100 mm and height of 15 mm. Super wide-ranging type head supports load control, and handles a broad spectrum of components from ultra-tiny chips of 03015mm,to ultra-large components of 55 x 100 mm and tall components of heights to 28 mm.

Super wide-ranging type head supports load control, and handles a broad spectrum of components from ultra-tiny chips of 03015mm,to ultra-large components of 55 x 100 mm and tall components of heights to 28 mm.

| Model | YSM20R |

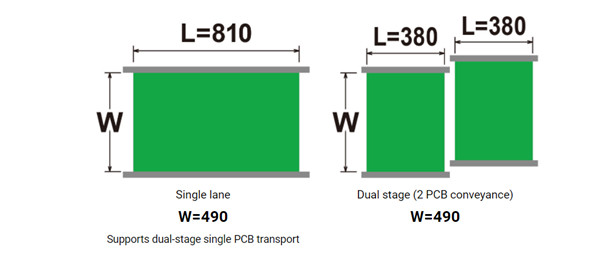

| Applicable PCB | Single lane L810 x W490 to L50 x W50 Dual stage Note: For X-axis 2-beam option only 1PCB conveyance: L810 x W490 to L50 x W50 2PCB conveyance: L380 x W490 to L50 x W50 |

| Head / Applicable components | High-Speed Multi (HM) Head *0201mm to W55 x L100mm, Height 15mm or lessOdd-shaped components (FM: Flexible Multi) head: 03015mm to W55 x L100mm, Height 28mm or less |

| Mounting capability(under optimum conditions as defined by Yamaha Motor) | X axis 2-beam: High-speed multi-purpose (HM: High-speed Multi) head x 2 95,000CPH |

| Mounting accuracy | ±0.035mm (±0.025mm) Cpk≧1.0 (3σ) (under optimum conditions as defined by Yamaha Motor when standard evaluation materials are used) |

| Number of component Types | Fixed plate: Max. 140 types (conversion for 8mm tape feeder) Feeder carriage exchange: Max. 128 types (conversion for 8mm tape feeder) Trays for 30 types (Fixed type: max., when fitted with sATS30) and 10 types (Carriage type: max., when fitted with cATS10) |

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% 50/60Hz |

| Air supply source | 0.45MPa or more, in clean, dry state |

| External dimension (excluding projections) | L 1,374 x W 1,857 x H1,445mm (Main unit only) |

| Weight | pprox. 2,050kg (Main unit only) |

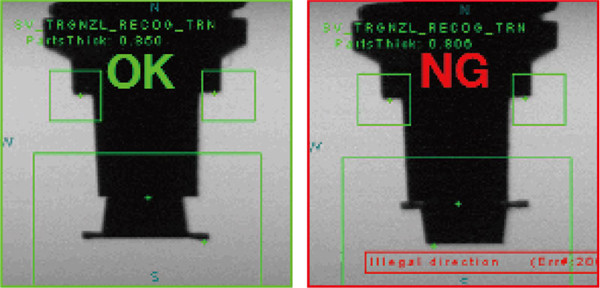

Detects pickup status and component’s presenge with no downtime loss.Mounting a new type wide-scan camera increases and expands recognition capability to support high speed mounting of components down to only □8 mm to □12 mm in size. Also, use of side lighting gives high-speed recognition of ball electrode components such as CSP (chip scale packages) and BGA (ball grid arrays).Achieving a common platform allows selecting from 1-beam and 2-beam for configuring the X-axis according to production mode and mounting capability.Conveyor system is selectable from dual stage, single lane. Supports PCB sizes to a max.L810 x W490 mm (Dual stage, single lane for conveying single PCB). Single lane also available in M size specifications (max. PCB size L360 x W490 mm) having superior cost performance.

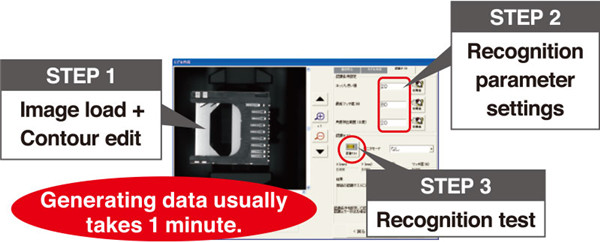

Detects pickup status and component’s presenge with no downtime loss.Mounting a new type wide-scan camera increases and expands recognition capability to support high speed mounting of components down to only □8 mm to □12 mm in size. Also, use of side lighting gives high-speed recognition of ball electrode components such as CSP (chip scale packages) and BGA (ball grid arrays).Achieving a common platform allows selecting from 1-beam and 2-beam for configuring the X-axis according to production mode and mounting capability.Conveyor system is selectable from dual stage, single lane. Supports PCB sizes to a max.L810 x W490 mm (Dual stage, single lane for conveying single PCB). Single lane also available in M size specifications (max. PCB size L360 x W490 mm) having superior cost performance. Automatic blow cleaning function keeps nozzle clean for long periods.Highly robust “High-speed Smart Recognition” that also creates recognition data for custom or unique components in a short time is now standard equipment.

Automatic blow cleaning function keeps nozzle clean for long periods.Highly robust “High-speed Smart Recognition” that also creates recognition data for custom or unique components in a short time is now standard equipment.